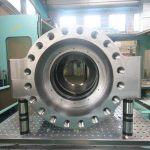

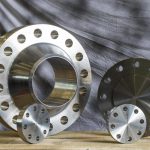

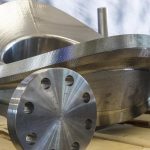

FULL METALLURGICAL SERVICES

TD Forge’s Quality System Structure

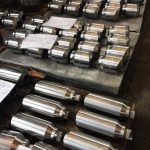

is based on ISO 9001 Company Quality Manual. Inspections during manufacturing activities are performed by qualified personnel in accordance with Quality Plans attached to 100% drawings under manufacturing. Our personnel also offer full metallurgic services: corrosion test, macrographic test, metallographic test, tensile testing, hardness testing, positive material identification (P.M.I.), liquid penetrant test (P.T.), ultrasonic test (U.T.) and magnetic particle inspection (M.T.).

Dimensional control of forgings fully machined to drawing are CMM ispected.

In addition to the required identification marking, 100% of our products are identified by a batch traceability number (BTN) which serves to identify the raw material pedigree or mill test report.